Why should your cleaning tools and utensils be color coded? It's a question we often hear, even though the reasoning is clear to many. Here’s how we explain it.

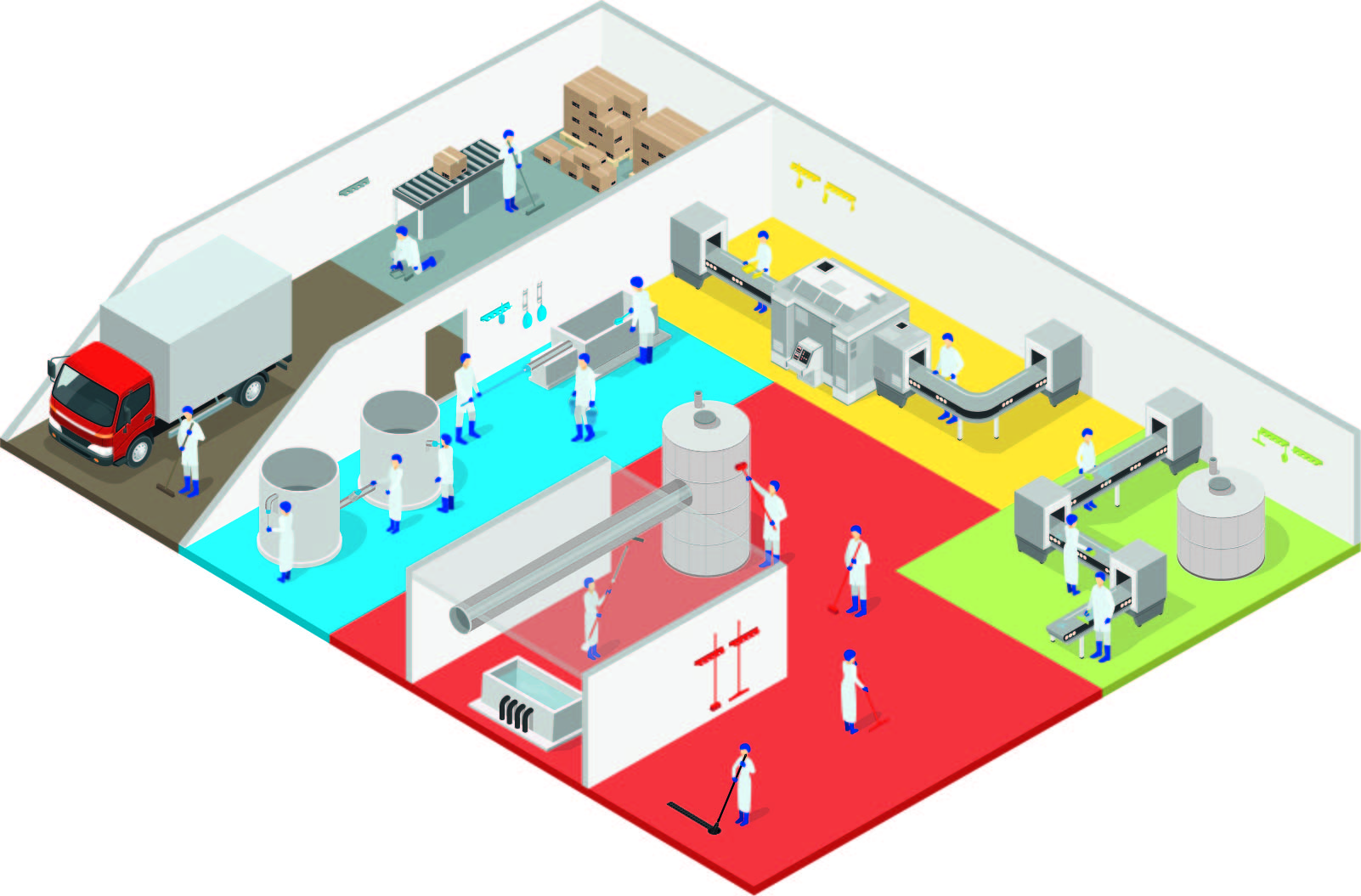

The short answer is that separating cleaning equipment, food handling tools, and other items into clearly defined, color-coded zones makes practical and commercial sense. It helps reduce the risk of cross-contamination between areas, ultimately improving food safety standards.

The longer explanation is that in food production and processing, strict systems are essential to prevent contamination and meet regulatory requirements. A well-designed color-coding system not only prevents cross-contamination but also ensures compliance with GFSI-approved food safety standards like BRC, FSSC 22000, IFS, and SQF.

GFSI-approved standards such as BRC, FSSC 22000, IFS, and SQF all emphasize the need for measures to prevent cross-contact and contamination.

BRC Global Standard for Food Safety Issue 8 requires color coding or labeling of cleaning equipment for identification.

FSSC 22000 Version 4.1 includes ISO standards that require controls over cross-contamination and cross-contact.

IFS Food Standard 6.1 states that the intended use of cleaning equipment must be clearly identified and used appropriately to avoid contamination.

SQF Code Edition 8 on Food Manufacturing emphasizes the importance of keeping functions, products, and zones separate due to associated risks.

Color coding aligns with the 5S LEAN system, which uses five steps—Sort, Set in order, Shine, Standardize, and Sustain—to ensure proper organization and ownership in production processes.

Whether you're looking for a quick answer or a detailed explanation, the benefits of color coding remain consistent:

- Reduced risk of contamination by microorganisms, allergens, or foreign bodies through clear separation of processes.

- Lower costs from product recalls and rejections due to minimized cross-contamination.

- Increased efficiency with easy access to tools and equipment, aligned with HACCP principles.

- Improved clarity and understanding across teams, regardless of language barriers.

- Enhanced workplace culture where employees take responsibility for their tools and zones.

- Prolonged equipment life through proper storage on hooks, hangers, or shadow boards.

- Cost savings from reduced replacement needs.

- Streamlined operations with fewer tools and better organization.

- A clean, safe, and professional environment that impresses customers, auditors, and visitors.

Color coding leads to more efficient operations and significantly reduces the risk of contaminated products reaching the market. This can result in costly recalls and damage to your brand reputation.

Contact us at Vikan today, and let one of our experts conduct a site survey at your facility. We will create a tailored color-coding plan to enhance your operation's efficiency, safety, and hygiene.

Contact us

Recent blog posts

Control of foreign bodies from cleaning equipment and utensils

This blog post provides information on selection and maintenance of food industry cleaning tools and utensils, with regard to minimising the risk of product contamination by foreign bodies.

Satisfaction survey results – and a big ‘Thank you’!

Customer satisfaction is a top priority at Vikan, and every couple of years we put ourselves to the test by asking our customers how they think we’re doing.

Outstanding Ultra Safe Technology cleaning standard

Easy to clean Vikan Ultra Safe Technology products have delivered an outstanding cleaning standard for a large UK deli and meats manufacturer.

613 Lace Front Wig

Xuchang KANAZI Hair Products Co., Ltd. , https://www.kanazihair.com