1 The development of newsprint industry Newsprint is a large variety of paper industry. The total output of newsprint in the world accounts for 12% of the total output of paper and paperboard. The output of newsprint in our country is only 3.79% of the total amount of paper and paperboard, and it is under the planned economic system to arrange production according to needs and is listed as a national mandatory plan. Both the supply and demand and price are stipulated by the state, and even if there is a small amount of imports, it is only the need for the varieties to be adjusted and supplemented.

Because of the long-term planned economic system, the technology equipment of the nine state-owned newsprint production enterprises in China are outdated, the quality of the varieties is not high, the production efficiency is low, the corporate social burden is heavy, the cost is high, the company lacks funds, and the upgrading and transformation are ineffective.

In the 1990s, the rapid development of China's newspaper and periodical publishing industry brought in the most advanced printing equipment from abroad. It was difficult for domestic newsprint to meet the requirements for high-speed color printing. In addition, foreign newsprint paper was dumped at a low price, and thus the newspaper office imported a large amount of foreign materials.

This shock caused great difficulties for the SOEs' factories. The production capacity of 800,000 tons (1996) dropped to 700,000 tons (1997), and the output of the nine major paper mills fell to 590,000 tons. The general lack of operating rate, downtime conversion, although the price is still difficult to sell, a large backlog of companies, capital circulation difficulties, employees laid off, frequent losses. This is a long-term state-owned enterprise under the planned economic system. It has been affected by fierce market competition in the market economy. The quality of state-owned enterprises cannot meet the new requirements of the newspapers, the cost and selling prices are not competitive, and international paper merchants dump at a low price.

The state has adopted many measures of support and encouragement for the newsprint industry, which has enabled anti-dumping cases to be won, tax rates for restrictive sliding tax have been imposed, and some state-owned enterprises have purchased backlogs of stocks. The newspaper has called on newspapers to help paper mills overcome difficulties together. At the same time, the company also made its utmost efforts to try its best to improve quality and reduce costs under its own conditions. It also paid close attention to the reform and marketing of the company and eased the difficulties of the company. At the same time, the first foreign newsprint company (Shanghai Hansong Potential Paper Co., Ltd.) was put into operation in China, enabling the state-owned enterprises to realize that enterprises must undergo restructuring and transformation, improve their competitiveness, and be able to deal with international and domestic competition. Otherwise, they cannot survive. Say development. As a result, the requirements for renewal and transformation of enterprises are more pressing and intense. The country also recognizes that the newsprint industry has not been able to achieve the consequences of long-term transformation. This has placed the papermaking industry, especially newsprint companies, in a renewal process.

From 1999 to 2000, there were three batches of loans, discount loans to support numerous newsprint projects. Such as: Nanping Paper Factory introduced the most advanced width width of 5.5m, speed 1800m/min high speed paper machine, has been put into operation early last year, received good results; Guangzhou paper mills imported width 6.4m speed up after transformation The 1200m/min paper machine was officially put into production in July last year with remarkable results. The paper machine imported from Qiqihar Paper Factory is similar to Nanping, and is nearing completion and will soon be put into production; Yueyang Paper Factory adopts imported 3940mm paper machine with 680-750m/ Min production newsprint, quality and cost are competitive, stand-alone production of up to 70,000 tons / year; Jilin paper mill # 10 paper machine will make the paper output will be doubled to achieve high efficiency and high quality requirements; Jiangxi, stone The Yantai Second Paper Factory has been set to import 6.4m, 1600m/min with micro-coated high-speed paper machine; Yibin Paper Factory has also approved 90,000 tons of new projects. In this way, the original state-owned nine major newsprint mills, except the Yalujiang Paper Mill, have modern new technology and equipment projects. This is the first time in the history of the state-owned enterprises newsprint industry that such a large-scale comprehensive renovation and transformation. At the same time, the newly-incorporated Shandong Huatai Company's imported second-hand 6.04m and 1200m/min paper machine newsprint production lines have entered the end and will soon be put into operation. Another Zhejiang jinjiang company's 50,000-ton/year production line is about to start production. It is reported that Longyan Paper Factory also has arrangements for increasing production and transformation. The total production capacity of these new products will reach 1.4 million tons/year, with a stand-alone production scale of 140,000 tons/year, and 4 units of up to 200,000 tons/year (counts: 4 imported paper machines and 3 imported used papers. Machines, two remodeling paper machines, and one domestic paper machine will all be put into production in 2003.

This round of transformation of domestic enterprises will undoubtedly change the face of China's newsprint industry and create preliminary conditions for participating in international competition. However, domestic companies must improve their international competitiveness and refresh their technical equipment. This is only one aspect. More importantly, it is necessary to make efforts in reforming and reforming enterprises. To implement an advanced modern enterprise system, it is necessary to further plan the transformation and development of enterprises and increase the scale of enterprises and stand-alone machines (the size of enterprises should be 300,000-500,000 tons, and the stand-alone scale should be 200,000 tons / year). All enterprises must solve the problem of raw material bases, and must have a steady source of raw materials with good quality and low cost. The self-employed high-yield forest should be developed as the first workshop of the company and completely controlled in the hands of the enterprise (Foreign wood chips cost 15-20USD/m3, now it is up to 50USD/m3 in China, if it can reduce self-operated taxes, it can be reduced to 25-30USD/ M3). To reduce energy costs, the use of cogeneration (power supply costs down to 2 cents/kWH, steam supply costs 5-7USD/tonne). We must pay great attention to water conservation and work hard to reduce water consumption (15-17m3/ton of paper, including foreign newsprint paper consumption). We will strive to reduce the unit consumption of fiber raw materials and energy and strive to increase production efficiency. The total efficiency of foreign newsprinters is 92%, the production capacity is approximately 48.8g/m2, which is about 800kg/cm.d, and the highest is 1100kg/cm·d. Our current production equipment is only 300kg/cm·d.

Physical labor productivity is an important indicator for a company. The actual labor productivity of foreign newsprint industry is roughly 700-1,000 tons/person.year. At the same time, we must pay attention to environmental protection and make our company a green, clean, garden-style factory. I think that domestic companies must use all available resources and funds. After the completion of this renovation and transformation, the second phase of technical equipment should be updated to ensure that an enterprise should have at least two advanced high-speed production machines. About 200,000 tons each, the scale of the company reached 400,000 tons. With such a foundation and modern enterprise mechanisms, it is possible to compete with international counterparts. We hope that in the near future, we can see that the domestic newsprint industry has a rational layout, self-sufficiency in green materials, advanced technology and equipment, high efficiency, good quality, and low cost, and it can be in line with international standards in business management, not only in domestic sales, You can also hit the international market.

According to the state’s newsprint that was imported after the accession to the WTO, the tariff rate for the 8th year will be reduced from 15% to 5%, while for other varieties, the current tax rate will be reduced to 5% to 7.5% within 3-5 years. In the policy tax system, Provide sufficient time for domestic companies to carry out restructuring, reform and transformation to achieve a level of international competitiveness. Of course, some uncompetitive enterprises will certainly be eliminated in the fierce competition.

2 With regard to the issue of foreign investment in China's newsprint industry, the experts conducted several discussions and had different opinions.

One view is that now is the era of reform and reform, and the national construction and development funds are not enough. To attract foreign capital is also a channel for financing. It can solve the difficulties of China's own lack of development funds, introduce advanced technology and equipment, and advanced enterprise management systems. Domestic production will reduce imports, provide opportunities for social employment, and increase national tax revenue. The introduction of foreign capital can introduce a competition mechanism, which will promote the reform and transformation of state-owned enterprises. It believes that it should not be blocked to attract foreign investment and it should be introduced with a positive attitude.

Another view is that the role and advantage of attracting foreign investment to China to develop newsprint is undeniable, but newsprint is a key species of the country. The production and management of domestic enterprises have just been transferred to the market from the planned economic system of the past decades. The economy cannot be compared with foreign-funded enterprises in any respect. Therefore, the introduction of large amounts of foreign investment without giving state-owned enterprises the opportunity and conditions for restructuring, reforming, and reforming is undoubtedly an unequal competition that places state-owned enterprises under strong conditions. This will inevitably lead to the inability of enterprises to survive. In a few years, state-owned enterprises will disappear in the newsprint industry and be replaced by foreign-funded enterprises. This is undesirable and unfair.

Therefore, we should appropriately and effectively control the scale and speed of the introduction of foreign capital, so that both foreign-funded enterprises can be introduced, but also allow state-owned enterprises to pay close attention to their own restructuring and renewal, to state-owned enterprises in time and space conditions. After transformation, the international competitiveness has been improved, and on this basis, the scale and speed of the introduction of foreign capital will be gradually relaxed, and the control will be generally appropriate. In this way, the newsprint industry of the state-owned enterprises will not only get the opportunity to reform and transform and enhance competitiveness, but also make the introduction of foreign investment moderately and gradually reach the scale and appropriateness of the introduction of elements. The whole country's newsprint industry will fly together and there will be a balanced and orderly situation.

I think that opening up should be conducive to the healthy development of China's national economy. The overall policy-oriented country has made it clear that there is a different industry, variety, form, region, time, and the scale and speed of development. Although the state has already introduced the introduction of industrial policies, the specific varieties and the introduction of progress should be determined from the status quo and needs of our country's economic development as well as its advantages and disadvantages. When choosing two different opinions, I agree with the latter. In addition, the introduction of foreign capital, especially newsprint, must take into account such issues as rational distribution, appropriate scale, advanced technology, introduction of time, and balance of domestic needs. However, I agree that the total supply should be greater than the total demand, and competition and adaptive development can be formed. Raw materials, energy, environmental protection and water resources should also be considered. Many large international companies want to invest in China and even want to control China to occupy the newsprint market. We should be especially careful and alert.

3 The impact of WTO entry on the newsprint industry The third issue is that after China's accession to the WTO, it will further open up imports and reduce tariffs. This will have a greater impact on newsprint of state-owned enterprises and a specific analysis should be made. 3.1 Domestic demand for newsprint. Since 1998, the demand for newsprint in China has increased by a large margin. Domestic production experienced difficulties from 1996 to 1997. The country has adopted corresponding policies (anti-dumping and sliding tax rates and crackdown on smuggling) from the macro level, improving quality and improving The management reduced the costs and increased the production volume so that the newspapers could accept it. Therefore, the import volume of newsprint fell to 236,400 tons in 1998 and 242,600 tons in 1999, accounting for 17.0% of the consumption of 1.45 million tons in the current year. In 2000, newsprint produced in the country developed in a better direction. The total output was 1.455 million tons, and the import volume was 210,000 tons, which accounted for 14% of the estimated consumption of 1.5 million tons in the current year. This should be normal as well. . With the domestic enterprises upgrading after the production will greatly increase, the quality of the varieties have also greatly improved and improved, domestic newspapers will certainly welcome and accept the supply of domestic production companies. It is estimated that the consumption in 2005 will be 2.4-2.5 million tons, and domestic production capacity can reach this level in 2003. Therefore, from the point of view of supply and demand after the accession to the WTO, a large number of imported newsprint may be few.

3.2 Variety, quality condition. Among the total domestic production, the varieties and total volumes that meet the requirements for high-speed color printing have increased year by year. Currently, they account for about 35%. By 2003, they will increase to more than 60%. However, some of the old production technology and equipment will be eliminated and part of the improvement will be improved. The quality will also be higher than the original one. Furthermore, the demand for the variety and quality of newsprint from domestic newspapers is not always upscale, and there are different levels of needs. Domestic production of different grades of newsprint supplies different newspapers, and even the papers used in the same newspaper sometimes have different grades and qualities. For example, holidays are not the same as usual, and the color and interior pages of the cover are different. This is demand and sale. Prices and availability are determined. Therefore, in terms of quality and quality, not all newspaper companies will import newsprint. Moreover, the proportion of new equipment used to produce high-grade newsprint by state-owned enterprises has gradually taken a dominant position. Therefore, after the accession to the WTO, there will not be a lot of imports in variety and quality.

3.3 Supply price situation. I want to do a statistical analysis, you can see the comparison between domestic paper and imported paper (Table omitted).

Note: China-made medium-sized paper generally refers to paper with better quality of state-owned enterprises. Medium-low paper generally refers to poor quality of state-owned enterprises or small paper mill paper; domestic paper price refers to the ex-factory price announced at that time, and the actual transaction price differs from market to market, and is often lower than Actually announced price; imported paper medium-low paper is generally Asian Indonesia, Philippines, some Russian and South African paper, etc.; imported paper

Because of the long-term planned economic system, the technology equipment of the nine state-owned newsprint production enterprises in China are outdated, the quality of the varieties is not high, the production efficiency is low, the corporate social burden is heavy, the cost is high, the company lacks funds, and the upgrading and transformation are ineffective.

In the 1990s, the rapid development of China's newspaper and periodical publishing industry brought in the most advanced printing equipment from abroad. It was difficult for domestic newsprint to meet the requirements for high-speed color printing. In addition, foreign newsprint paper was dumped at a low price, and thus the newspaper office imported a large amount of foreign materials.

This shock caused great difficulties for the SOEs' factories. The production capacity of 800,000 tons (1996) dropped to 700,000 tons (1997), and the output of the nine major paper mills fell to 590,000 tons. The general lack of operating rate, downtime conversion, although the price is still difficult to sell, a large backlog of companies, capital circulation difficulties, employees laid off, frequent losses. This is a long-term state-owned enterprise under the planned economic system. It has been affected by fierce market competition in the market economy. The quality of state-owned enterprises cannot meet the new requirements of the newspapers, the cost and selling prices are not competitive, and international paper merchants dump at a low price.

The state has adopted many measures of support and encouragement for the newsprint industry, which has enabled anti-dumping cases to be won, tax rates for restrictive sliding tax have been imposed, and some state-owned enterprises have purchased backlogs of stocks. The newspaper has called on newspapers to help paper mills overcome difficulties together. At the same time, the company also made its utmost efforts to try its best to improve quality and reduce costs under its own conditions. It also paid close attention to the reform and marketing of the company and eased the difficulties of the company. At the same time, the first foreign newsprint company (Shanghai Hansong Potential Paper Co., Ltd.) was put into operation in China, enabling the state-owned enterprises to realize that enterprises must undergo restructuring and transformation, improve their competitiveness, and be able to deal with international and domestic competition. Otherwise, they cannot survive. Say development. As a result, the requirements for renewal and transformation of enterprises are more pressing and intense. The country also recognizes that the newsprint industry has not been able to achieve the consequences of long-term transformation. This has placed the papermaking industry, especially newsprint companies, in a renewal process.

From 1999 to 2000, there were three batches of loans, discount loans to support numerous newsprint projects. Such as: Nanping Paper Factory introduced the most advanced width width of 5.5m, speed 1800m/min high speed paper machine, has been put into operation early last year, received good results; Guangzhou paper mills imported width 6.4m speed up after transformation The 1200m/min paper machine was officially put into production in July last year with remarkable results. The paper machine imported from Qiqihar Paper Factory is similar to Nanping, and is nearing completion and will soon be put into production; Yueyang Paper Factory adopts imported 3940mm paper machine with 680-750m/ Min production newsprint, quality and cost are competitive, stand-alone production of up to 70,000 tons / year; Jilin paper mill # 10 paper machine will make the paper output will be doubled to achieve high efficiency and high quality requirements; Jiangxi, stone The Yantai Second Paper Factory has been set to import 6.4m, 1600m/min with micro-coated high-speed paper machine; Yibin Paper Factory has also approved 90,000 tons of new projects. In this way, the original state-owned nine major newsprint mills, except the Yalujiang Paper Mill, have modern new technology and equipment projects. This is the first time in the history of the state-owned enterprises newsprint industry that such a large-scale comprehensive renovation and transformation. At the same time, the newly-incorporated Shandong Huatai Company's imported second-hand 6.04m and 1200m/min paper machine newsprint production lines have entered the end and will soon be put into operation. Another Zhejiang jinjiang company's 50,000-ton/year production line is about to start production. It is reported that Longyan Paper Factory also has arrangements for increasing production and transformation. The total production capacity of these new products will reach 1.4 million tons/year, with a stand-alone production scale of 140,000 tons/year, and 4 units of up to 200,000 tons/year (counts: 4 imported paper machines and 3 imported used papers. Machines, two remodeling paper machines, and one domestic paper machine will all be put into production in 2003.

This round of transformation of domestic enterprises will undoubtedly change the face of China's newsprint industry and create preliminary conditions for participating in international competition. However, domestic companies must improve their international competitiveness and refresh their technical equipment. This is only one aspect. More importantly, it is necessary to make efforts in reforming and reforming enterprises. To implement an advanced modern enterprise system, it is necessary to further plan the transformation and development of enterprises and increase the scale of enterprises and stand-alone machines (the size of enterprises should be 300,000-500,000 tons, and the stand-alone scale should be 200,000 tons / year). All enterprises must solve the problem of raw material bases, and must have a steady source of raw materials with good quality and low cost. The self-employed high-yield forest should be developed as the first workshop of the company and completely controlled in the hands of the enterprise (Foreign wood chips cost 15-20USD/m3, now it is up to 50USD/m3 in China, if it can reduce self-operated taxes, it can be reduced to 25-30USD/ M3). To reduce energy costs, the use of cogeneration (power supply costs down to 2 cents/kWH, steam supply costs 5-7USD/tonne). We must pay great attention to water conservation and work hard to reduce water consumption (15-17m3/ton of paper, including foreign newsprint paper consumption). We will strive to reduce the unit consumption of fiber raw materials and energy and strive to increase production efficiency. The total efficiency of foreign newsprinters is 92%, the production capacity is approximately 48.8g/m2, which is about 800kg/cm.d, and the highest is 1100kg/cm·d. Our current production equipment is only 300kg/cm·d.

Physical labor productivity is an important indicator for a company. The actual labor productivity of foreign newsprint industry is roughly 700-1,000 tons/person.year. At the same time, we must pay attention to environmental protection and make our company a green, clean, garden-style factory. I think that domestic companies must use all available resources and funds. After the completion of this renovation and transformation, the second phase of technical equipment should be updated to ensure that an enterprise should have at least two advanced high-speed production machines. About 200,000 tons each, the scale of the company reached 400,000 tons. With such a foundation and modern enterprise mechanisms, it is possible to compete with international counterparts. We hope that in the near future, we can see that the domestic newsprint industry has a rational layout, self-sufficiency in green materials, advanced technology and equipment, high efficiency, good quality, and low cost, and it can be in line with international standards in business management, not only in domestic sales, You can also hit the international market.

According to the state’s newsprint that was imported after the accession to the WTO, the tariff rate for the 8th year will be reduced from 15% to 5%, while for other varieties, the current tax rate will be reduced to 5% to 7.5% within 3-5 years. In the policy tax system, Provide sufficient time for domestic companies to carry out restructuring, reform and transformation to achieve a level of international competitiveness. Of course, some uncompetitive enterprises will certainly be eliminated in the fierce competition.

2 With regard to the issue of foreign investment in China's newsprint industry, the experts conducted several discussions and had different opinions.

One view is that now is the era of reform and reform, and the national construction and development funds are not enough. To attract foreign capital is also a channel for financing. It can solve the difficulties of China's own lack of development funds, introduce advanced technology and equipment, and advanced enterprise management systems. Domestic production will reduce imports, provide opportunities for social employment, and increase national tax revenue. The introduction of foreign capital can introduce a competition mechanism, which will promote the reform and transformation of state-owned enterprises. It believes that it should not be blocked to attract foreign investment and it should be introduced with a positive attitude.

Another view is that the role and advantage of attracting foreign investment to China to develop newsprint is undeniable, but newsprint is a key species of the country. The production and management of domestic enterprises have just been transferred to the market from the planned economic system of the past decades. The economy cannot be compared with foreign-funded enterprises in any respect. Therefore, the introduction of large amounts of foreign investment without giving state-owned enterprises the opportunity and conditions for restructuring, reforming, and reforming is undoubtedly an unequal competition that places state-owned enterprises under strong conditions. This will inevitably lead to the inability of enterprises to survive. In a few years, state-owned enterprises will disappear in the newsprint industry and be replaced by foreign-funded enterprises. This is undesirable and unfair.

Therefore, we should appropriately and effectively control the scale and speed of the introduction of foreign capital, so that both foreign-funded enterprises can be introduced, but also allow state-owned enterprises to pay close attention to their own restructuring and renewal, to state-owned enterprises in time and space conditions. After transformation, the international competitiveness has been improved, and on this basis, the scale and speed of the introduction of foreign capital will be gradually relaxed, and the control will be generally appropriate. In this way, the newsprint industry of the state-owned enterprises will not only get the opportunity to reform and transform and enhance competitiveness, but also make the introduction of foreign investment moderately and gradually reach the scale and appropriateness of the introduction of elements. The whole country's newsprint industry will fly together and there will be a balanced and orderly situation.

I think that opening up should be conducive to the healthy development of China's national economy. The overall policy-oriented country has made it clear that there is a different industry, variety, form, region, time, and the scale and speed of development. Although the state has already introduced the introduction of industrial policies, the specific varieties and the introduction of progress should be determined from the status quo and needs of our country's economic development as well as its advantages and disadvantages. When choosing two different opinions, I agree with the latter. In addition, the introduction of foreign capital, especially newsprint, must take into account such issues as rational distribution, appropriate scale, advanced technology, introduction of time, and balance of domestic needs. However, I agree that the total supply should be greater than the total demand, and competition and adaptive development can be formed. Raw materials, energy, environmental protection and water resources should also be considered. Many large international companies want to invest in China and even want to control China to occupy the newsprint market. We should be especially careful and alert.

3 The impact of WTO entry on the newsprint industry The third issue is that after China's accession to the WTO, it will further open up imports and reduce tariffs. This will have a greater impact on newsprint of state-owned enterprises and a specific analysis should be made. 3.1 Domestic demand for newsprint. Since 1998, the demand for newsprint in China has increased by a large margin. Domestic production experienced difficulties from 1996 to 1997. The country has adopted corresponding policies (anti-dumping and sliding tax rates and crackdown on smuggling) from the macro level, improving quality and improving The management reduced the costs and increased the production volume so that the newspapers could accept it. Therefore, the import volume of newsprint fell to 236,400 tons in 1998 and 242,600 tons in 1999, accounting for 17.0% of the consumption of 1.45 million tons in the current year. In 2000, newsprint produced in the country developed in a better direction. The total output was 1.455 million tons, and the import volume was 210,000 tons, which accounted for 14% of the estimated consumption of 1.5 million tons in the current year. This should be normal as well. . With the domestic enterprises upgrading after the production will greatly increase, the quality of the varieties have also greatly improved and improved, domestic newspapers will certainly welcome and accept the supply of domestic production companies. It is estimated that the consumption in 2005 will be 2.4-2.5 million tons, and domestic production capacity can reach this level in 2003. Therefore, from the point of view of supply and demand after the accession to the WTO, a large number of imported newsprint may be few.

3.2 Variety, quality condition. Among the total domestic production, the varieties and total volumes that meet the requirements for high-speed color printing have increased year by year. Currently, they account for about 35%. By 2003, they will increase to more than 60%. However, some of the old production technology and equipment will be eliminated and part of the improvement will be improved. The quality will also be higher than the original one. Furthermore, the demand for the variety and quality of newsprint from domestic newspapers is not always upscale, and there are different levels of needs. Domestic production of different grades of newsprint supplies different newspapers, and even the papers used in the same newspaper sometimes have different grades and qualities. For example, holidays are not the same as usual, and the color and interior pages of the cover are different. This is demand and sale. Prices and availability are determined. Therefore, in terms of quality and quality, not all newspaper companies will import newsprint. Moreover, the proportion of new equipment used to produce high-grade newsprint by state-owned enterprises has gradually taken a dominant position. Therefore, after the accession to the WTO, there will not be a lot of imports in variety and quality.

3.3 Supply price situation. I want to do a statistical analysis, you can see the comparison between domestic paper and imported paper (Table omitted).

Note: China-made medium-sized paper generally refers to paper with better quality of state-owned enterprises. Medium-low paper generally refers to poor quality of state-owned enterprises or small paper mill paper; domestic paper price refers to the ex-factory price announced at that time, and the actual transaction price differs from market to market, and is often lower than Actually announced price; imported paper medium-low paper is generally Asian Indonesia, Philippines, some Russian and South African paper, etc.; imported paper

Product Description

The KSONE carbon fiber indoor Field Hockey Stick is designed for the advanced indoor field hockey player. 36.5,37.5 38 Inches. Features a late bow with a maxi toe.

|

Product name:

|

field Hockey Stick

|

|

Material:

|

Carbon fiber

|

|

Length:

|

36 .5 inch , 37 .5, 38 inch

|

|

Kinds

|

High, Medium, Low

|

|

Logo:

|

Customized printed logo

|

|

Shaft width:

|

50mm

|

|

Color:

|

Multiple

|

|

Balance Point:

|

40-/+ 10mm

|

Related Products

Company Profile

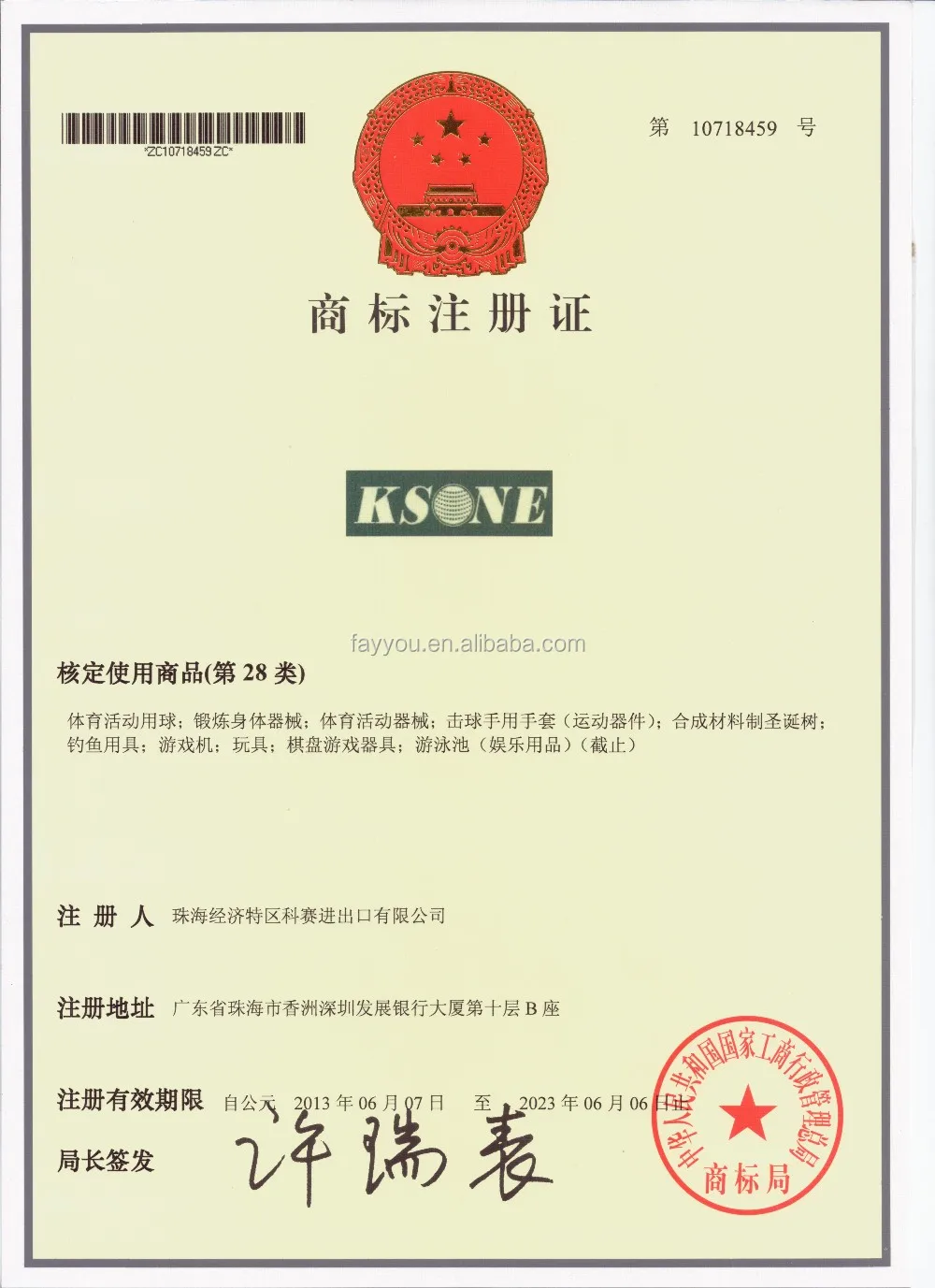

Fayyou Sport Co., Ltd.,subsidiary of Zhuhai Kesai Co Ltd. founded in 1997, is specialized in producing and promoting sports products including lacrosse,hockey, crossfit and massage products.

Kesai has professional experience in manufacturing, marketing and shipping, providing multiple services. Fayyou Sport was established in 2015 due to increasing sports business volume.

Kesai has professional experience in manufacturing, marketing and shipping, providing multiple services. Fayyou Sport was established in 2015 due to increasing sports business volume.

Certifications

Packing & Delivery

Hockey Stick

Composite Field Hockey Sticks,High Quality Field Hockey Sticks,Hockey Stick,Field Hockey Stick

FAY YOU SPORTS CO.,LTD , http://www.ksonelacrosse.com